The Muga Silk Fabric from Assam is a prized possession for everyone as it is the second most expensive silk in the world after Pashmina. Muga Silk Fabric is a variety of silk that is exclusively produced in Assam and has a GI (Geographical Indication) tag registered for it authenticity and place of origin. Let’s discover Golden Muga Silk from Assam! This blog explains its cultural significance, buying guide with prices, production process of various attire made out of Muga silk.

Why Muga Silk Fabric is So Expensive?

Muga Silk Fabric, primarily produced in Assam, sees an annual global production of only 270 tons, a stark contrast to the 250 million tons of cotton annually. However, its demand continues to rise due to its increasing popularity.

Secondly, the production of authentic muga silk can be mechanised or mass produced. It is simply not possible because of rearing condition of Muga silk worm (from which silk is produced), large amount of manual labour required to process the silk, geographical barriers to grow muga silkworm and its fodder in other parts of world.

To produce 500 grams of raw muga silk around 2500 silkworms are needed. On average, a saree (6-8 square metres) needs 1000 cocoons of muga silkworms. Now imagine, making silk out of 1000 silkworms just to make one saree. One acre of land can produce about 400 grams of Muga silk at a go. Besides, it requires intricate production process. One misstep can jeopardize the entire process. The weaving process of the Muga silk saree alone takes up one week to ten days to complete. That is why, it is one of the most expensive silks in the world.

Why Muga Silk Fabric is So Famous?

Muga Silk fabric gains its fame from several remarkable qualities. Its natural golden hue and bright glossy sheen set it apart. Renowned for its durability, Muga silk can last up to 1000 years, making it a favorite among royalty in the past. Unlike many fabrics, it retains its vibrant color even after multiple washes, and its finish actually improves with each wash, adding to its allure.Â

In Assam, there is a popular adage about Muga Silk Fabric- “ছাঁ তে শুকুৱা মুঠি তে লুকুৱা (Chhate Xukua Muthite Lukua)”. It means that the Muga Silk Fabric from Assam is so fine in its texture that it can be dried in a minute and a cloth can be hidden in the palm of our hands.

History and Evolution of Muga Silk in Assam

Muga Silk Fabric has deep roots in Assam, dating back to the arrival of Tibeto-Burman groups from China around 3000-2000 BC. Assam’s location on the ancient silk route linking Tibet, Burma, and Malaysia made Assam Silk a key export.

While silk production was widespread across Assam, Sualkuchi town stood out for its silk during the Pala dynasty and Ahom rule. Sualkuchi, established around the 11th century by King Dharmapala, became a hub for silk weaving. Dharma Pala reportedly brought weaver families from Barpeta to Sualkuchi, laying the foundation for a vibrant weaving community near modern-day Guwahati.

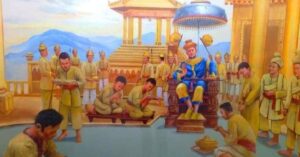

Under Ahom rule, silk gained royal status and was promoted by successive kings. Silk attire became customary for Ahom royalty and nobility, further enhancing the fabric’s significance and commercial value.

Unique properties of Muga Silk Fabric

- Softness: With a silky-smooth texture, Muga silk feels incredibly soft on the skin, providing a luxurious sensation akin to wearing nothing at all.

- Chemical-free: Made entirely from natural fibers, Muga silk is devoid of chemicals, resembling human hair in composition. It has 97 %, 3% fat, and wax, and contains 18 amino acids that are beneficial to your skin. Its production process involves no synthetic elements, making it environmentally friendly.

- Hypoallergenic: Muga silk stands out as the most allergen-free fabric, repelling dust mites and resisting various pollutants like dust, fungus, and mold.

- Health benefits: This fabric aids in skin moisture retention, promoting skin rejuvenation, delaying aging signs, and addressing dry skin issues by locking in moisture. It also offers UV protection.

- Longevity: Muga silk boasts high tensile strength, ensuring durability and a prolonged shelf life. It can last more than 1000 years even after occasional use.

Comparison with Other Types of Assamese Silk

Sericulture in Assam encompasses both mulberry and non-mulberry silkworm cultivation. Assam silk collectively refers to the three distinct varieties of indigenous silks produced in the region: Paat (mulberry), Eri, and Muga silks. Each type exhibits unique characteristics in terms of appearance and properties. Paat silk typically appears white or off-white, Muga silk boasts a honey or golden hue, and Eri silk presents a cream or off-white color. Eri silk encompasses endi, muga, and oak-tassar varieties. These silks are differentiated based on the species of silkworms they are derived from.

Endi and muga silks are regarded as indigenous to Assam and are primarily found in the region as well as in the foothills of Meghalaya.

Attires Made Out of Assamese Muga Silk

The motifs and designs of Assam are mostly taken from nature. These motifs and designs are known as phul (flower and floral pattern) or phuljali (flower and creeper). The bright hued diamond motif on contrasting background representing fine workmanship is typical and traditional feature of the tribal textiles of Assam.

Dresses crafted from Muga silk feature intricate embroidery inspired by floral motifs, foliage, trees, and traditional Bihu designs, imparting a distinctive and splendid appearance. Traditionally, this silk has been employed to fashion women’s attire known as “mekhela-sadar,” akin to sarees in Assam, as well as men’s kurtas.

Muga silk offers a wide range of possibilities, including hats, caps, scarves, wraps, stoles, quilts, bridal wear, upholstery, sarees, and kurtas.

Having gained popularity in the USA, Europe, South Africa, and the Middle East, the next destination for Muga Silk appears to be Japan, where designers are utilizing it to create kimonos and other traditional Japanese garments.

Muga Silk Fabric Extraction Process in Assam

Muga Silk is made out of Muga Silkworm. The silkworm commonly fed on Som (Persea bombycina) tree in Upper Assam and Sualu (Litsea monopetela) in Lower Assam. In addition, Mejankari (Littsea cubeba), Pan chapa (Magnolia sphenocarpa), Dighloti (Listsea salicifolia) are secondary host plants. However, worms fed on Som and Sualu trees will only produce first-grade Assamese Muga Silk. The complete process of making Muga Silk Fabric can simplified in the following steps:

- Silk moths lay thousands of eggs, which hatch into larvae called silkworms.

- The silkworms are fed mulberry leaves or other suitable food.

- The larvae grow into matured caterpillars and moult several times before they start forming their cocoons.

- The silkworm spins a net around itself and secretes a fluid that hardens upon contact with air, forming the cocoon.

- Each silkworm spins a filament of silk, which can reach up to 900 meters (about one mile), encasing itself within two to three days.

- The intact cocoons are boiled to kill the silkworms inside.

- The silk filament from the outside of the cocoon is retrieved by brushing, as it forms a continuous thread.

- The silk threads are wound onto a reel, and this stage is called raw silk.

- The raw silk undergoes a degumming process, where it is boiled in soap and water to remove sericin, resulting in soft and lustrous silk threads.

Main Centers of Silk Production in Assam

Primarily, bulk of the Muga Silk cultivation takes place in Upper Assam. Districts such as Lakhimpur, Dibrugarh, Sonari, Tinsukia are the main silk producing districts. A little bit is also done in the Garo and West Khasi hills of Meghalaya. All these raw materils then come mainly to Sulakuchi of Assam and its neighboring area such as Palashbari and Hajo (all three places in the Kamrup Metro district of Assam).

The main centre of silk handloom and textile industry is Sualkuchi. It is where these Muga Silk are processed and final products are released for market.

Women play a significant role in these kinds of textile industries as such silk producing activities are mostly home-based. More than 53% of Women are involved in various activities of sericulture. They along with men have been actively participating in all the sectors of sericulture from on-farm activities to fabric creation, marketing and consumption.